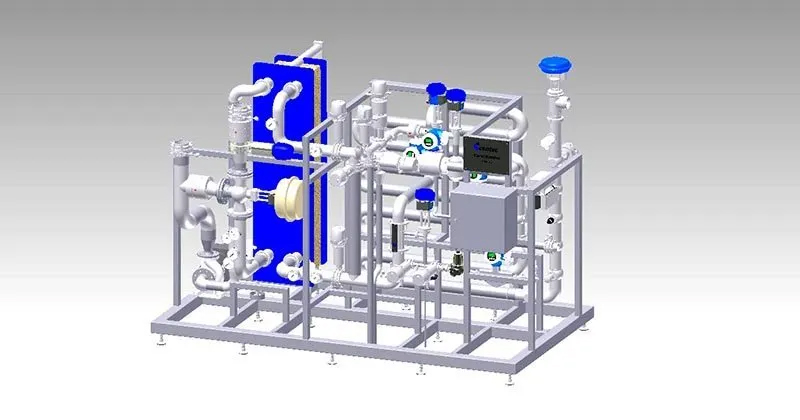

CarboBlender – High Gravity Blending & Carbonation for the Brewery Industry

For High Gravity Blending wort with high extract content is produced. During fermentation this leads to a beer with higher original gravity and alcohol content. Later in the process the high gravity beer is blended with deaerated water to reach the desired final original gravity and/or alcohol content. If this is done directly in front of the BBTs or even directly in front of the filler, brewery flexibility is increased significantly. Different beers (brands) can be produced from the same mother beer. In that way, the brewery can quickly react to changing market demands. For product carbonation the CarboBlender has a specifically designed Vortex-Venturi injector that feeds carbon dioxide in a very large number of very fine bubbles directly into the product stream. Due to high pressure and turbulent flow, the CO2 dissolves completely and absolutely homogeneously in a very short time. At the end of the dissolving path a control valve is installed. This valve keeps the pressure in the system constant and above the saturation pressure. The flows and the content of original gravity and alcohol are permanently monitored and adjusted by high precision ratio control. Therefore, the system is equipped with high precision flow meters and in-line sensors made by Centec. Centec have decades of experience in the development and manufacturing of own precision instruments for alcohol and CO2 control.

CarboBlender

Carboblending combines High Gravity Blending (HGB) and carbonation in one process step. The process allows producing different beers (brands) from one or few mother beers. Brewery productivity is thereby maximized for a comparatively small brew house capacity and a low number of fermentation tanks.